Image Source: Google

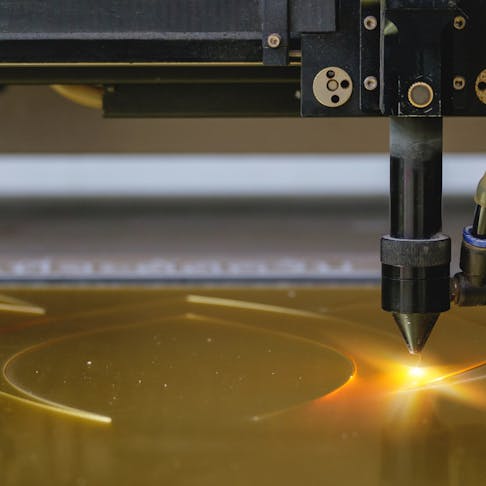

In the world of design and manufacturing, innovation is key to standing out and making an impact. One of the technologies that have revolutionized the industry is polymer laser cutting. This cutting-edge process allows designers to unleash their creativity and transform their visions into reality with precision and efficiency. Let's explore how polymer laser cutting is changing the game when it comes to creating stunning designs.

The Basics of Polymer Laser Cutting

Polymer laser cutting is a process that uses a high-powered laser to cut through various types of polymers with extreme precision. The laser beam is focused on the material, causing it to melt, vaporize, or burn, leaving behind a high-quality finish. This technology allows for intricate designs to be cut with accuracy, making it ideal for a wide range of applications in the design and manufacturing industries.

How Polymer Laser Cutting Works

- The material is placed on a flatbed or within a rotary device.

- The laser beam is directed onto the material, cutting through it based on the designer's specifications.

- The heat from the laser vaporizes the material, leaving a clean and precise edge.

Benefits of Polymer Laser Cutting

- Precision: Laser cutting offers unparalleled precision, allowing for intricate designs to be created with ease.

- Efficiency: The process is highly efficient, enabling designers to quickly iterate and produce high-quality prototypes.

- Versatility: Polymer laser cutting can be used on a wide range of materials, including acrylic, PET, polycarbonate, and more.

- Cleanliness: The laser produces clean cuts without the need for additional finishing, saving time and resources.

Applications of Polymer Laser Cutting

The versatility of polymer laser cutting makes it a valuable tool for a wide range of applications across different industries. Here are some of the common uses of this innovative technology:

Signage and Displays

From eye-catching retail displays to informative signage, polymer laser cutting is widely used to create visually appealing and durable products for marketing and branding purposes.

Prototyping and Product Development

Designers and engineers leverage polymer laser cutting to quickly prototype new products and iterate on designs, speeding up the development process and reducing time to market.

Art and Decorative Applications

Artists and designers use polymer laser cutting to produce intricate artworks, decorative pieces, and unique installations that push the boundaries of creativity and design.

Challenges and Considerations

While polymer laser cutting offers numerous benefits, there are also some challenges and considerations to keep in mind when utilizing this technology:

Material Selection

- Not all materials are suitable for laser cutting, so it's essential to choose the right type of polymer for the desired application.

Design Complexity

- Highly complex designs may require additional time and expertise to execute correctly, so it's important to consider the complexity of the design beforehand.

Maintenance and Safety

- Regular maintenance of the laser cutting equipment is crucial to ensure optimal performance and safety for the operators.

Conclusion

Polymer laser cutting is a game-changer in the world of design and manufacturing, offering designers the ability to unleash their creativity and bring their visions to life with precision and efficiency. By understanding the basics of polymer laser cutting, exploring its applications, and being aware of the challenges involved, designers can leverage this technology to create stunning designs that make a lasting impact.